Adoption View

Vision & Mission

Vision

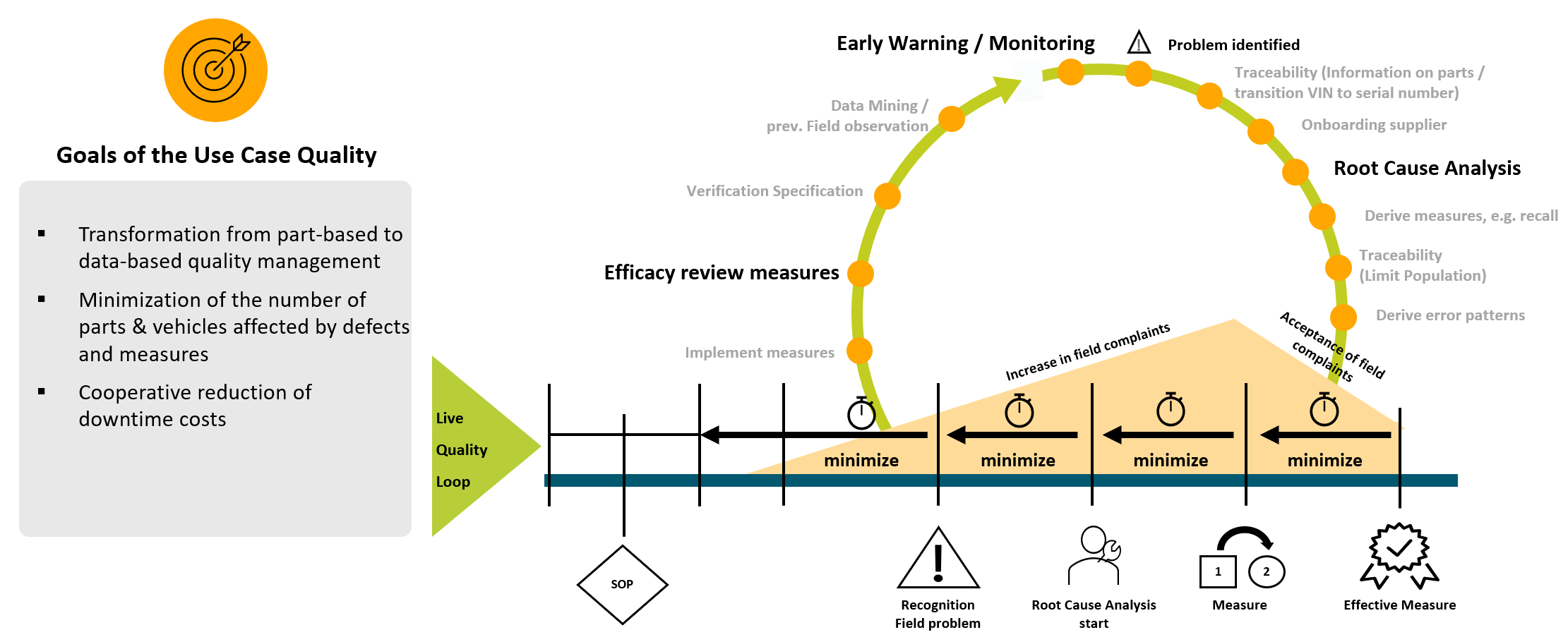

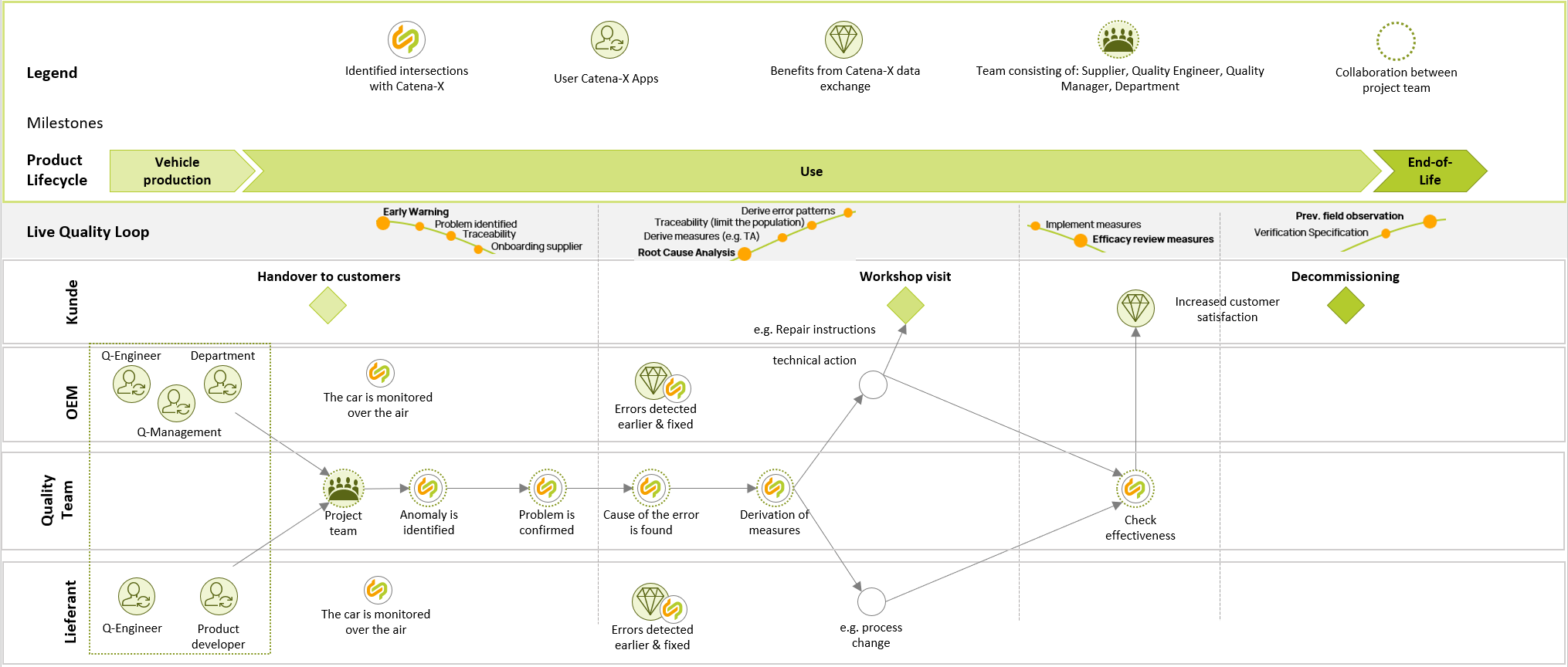

Our vision is to move from parts-based quality management on a bilateral level between supplier and customer to a data-based approach across the OEM-n-Tier chains of value creation to enable a network approach for producing and ensuring product quality.

The Quality KIT enables data provider and consumer to exchange and analyse existing data across company boundaries on a daily basis, securely and easily. By merging the OEM's field quality data and the supplier's product information, a new level of transparency is achieved in a joint analysis (single point of information). This leads to earlier failure detection, faster cooperation between partners and acceleration of root cause analysis. Once the root cause of the problem is known, corrective actions can be targeted to the products and vehicles that have the quality problem using Catena-X traceability capabilities. The containment minimises the number of parts & vehicles for which corrective actions need to be implemented.

This KIT enables quality app provider to deliver solutions for quality data analysis including tracebility and notification functionalities.

Mission

The Quality KIT provides the necessary standards, aspect models, technical data pipeline specifications and business logics on how to estabilish a soverein exchange of quality related data along the OEM-Tier n chain. All the components mentioned are based on the following principles:

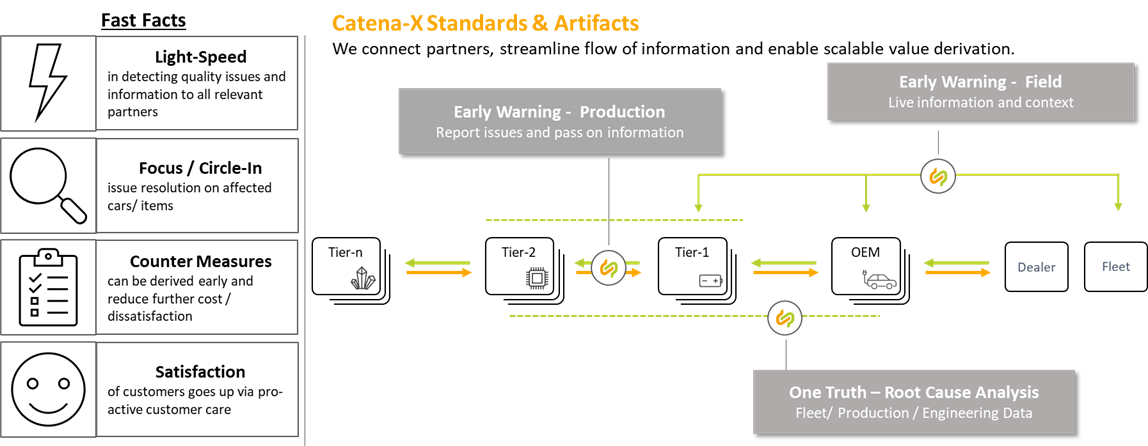

- We bring together data from suppliers and manufacturers (OEM).

- Data exchange between data provider and consumer complies with the Catena-X network's data sovereignty principles.

- Data exchange enables each partner to use the applications of their choice for data analysis features like Early Warning and Root Cause Analysis.

- We standardize data models incl. their assets

- Data exchange in the current Quality KIT version is described as a common requirement.

- Analysis methods and algorithms that are realized in the quaity applications are not part of any standardization. It is desirable that different tools deliver different results Specialisation of tools is valuable.

In sum this KIT enables quality management to substantially increase speed in resolving quality problems and reach a new level on transparency and traceability.

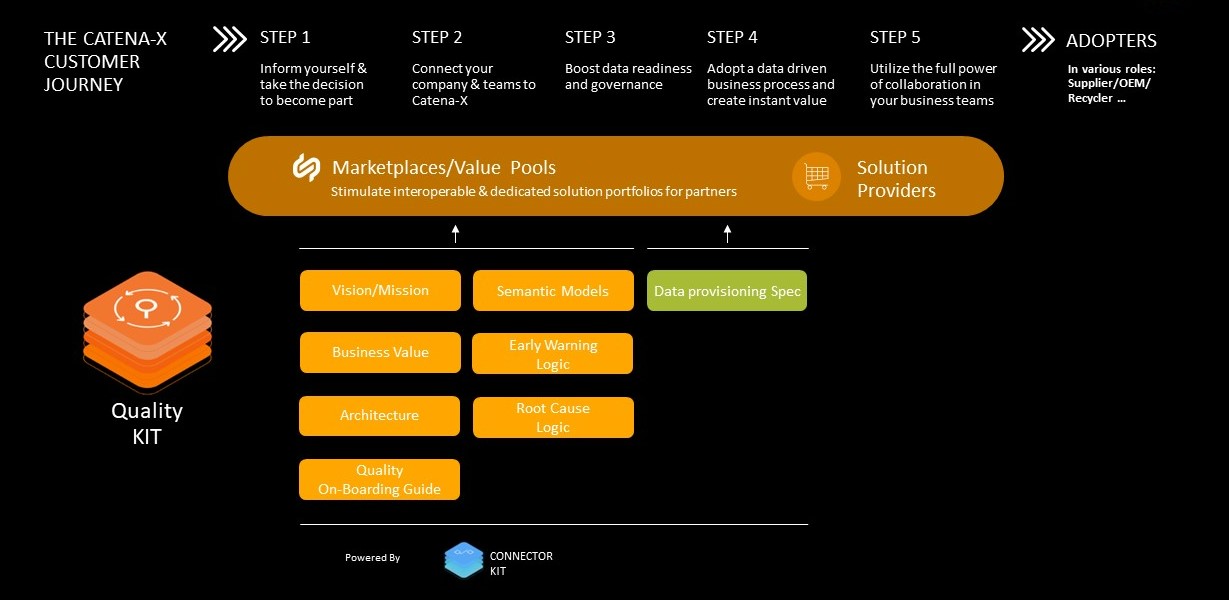

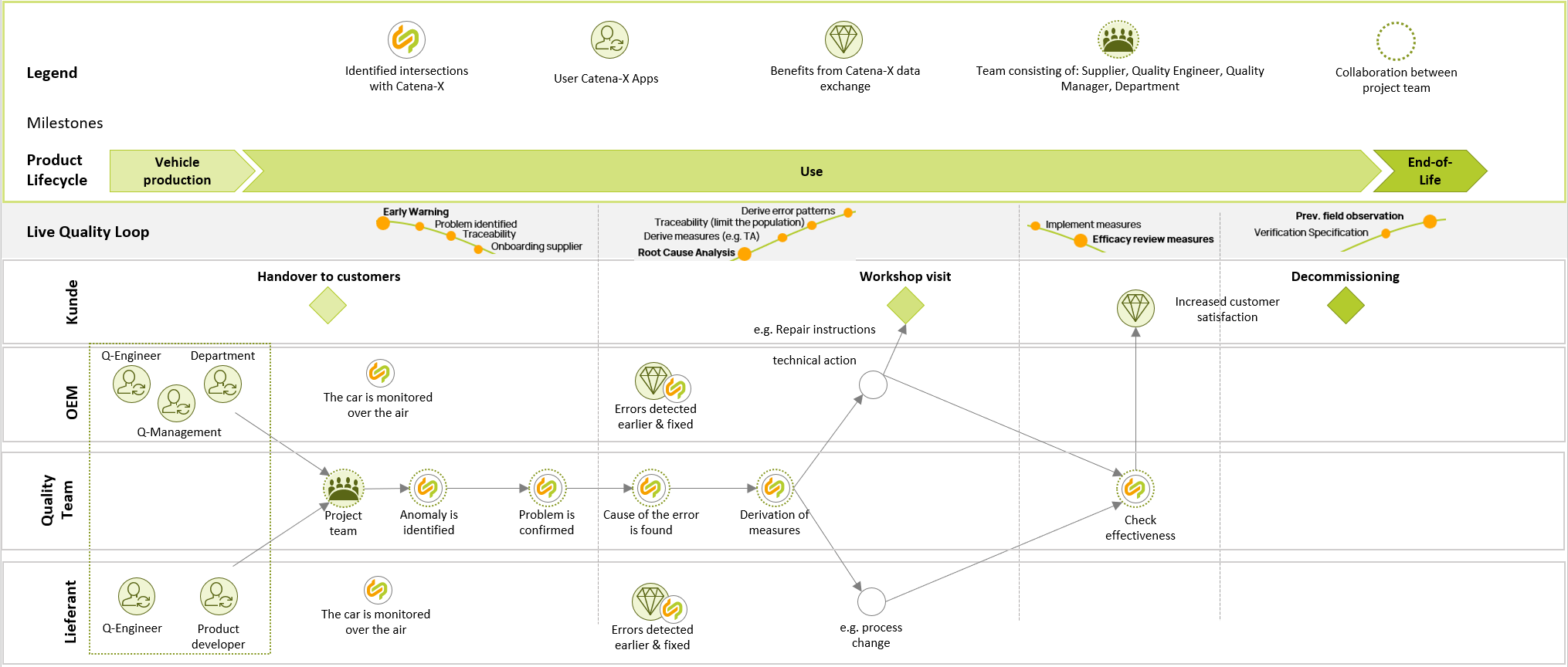

Customer Journey

With the Quality KIT, we support the Catena-X customer journey for our adopters and solutions providers.

Business Value

Through the standardized specifications described in the “Quality-KIT” – mainly the semantic models and data exchange process – data providers & consumers can build up a soverreign and trusty data exchange pipeline with their partner companies and reduce investment and implementation costs to integrate data based quality processes in their company inhouse process and IT landscape.

Furthermore, quality application providers can also reduce the implementation effort and enter potential new markets providing specific analytic capabilities.

Use Case

Status Quo / Today's challenge

In today’s global and complex collaboration models quality does not emerge as the sum of the quality contributions of the individual partners in the value chain of OEM and suppliers, but rather because of the networking of the partners involved.

The existing conventional bilateral working models do not account for this. There is no operative network in the industry with a substantial coverage of elements of the value chains that provides the necessary means for collaborative quality management with all involved partners.

From Quality Management perspective, the main challenge within the automotive industry is to define and implement inter-organizational end-to-end data chains across the whole automotive partner chain to empower data driven quality use cases.

Main challenges to ensure a trustful and scalable cooperation are:

- Trustful and sovereign data exchange mechanism including ...

- legal contracts and access/usage policy framework along the complete data chain

- Standardized data pipeline

- Aligned standard data exchange, e.g. file format and transfer

- Standardized data models

Benefits

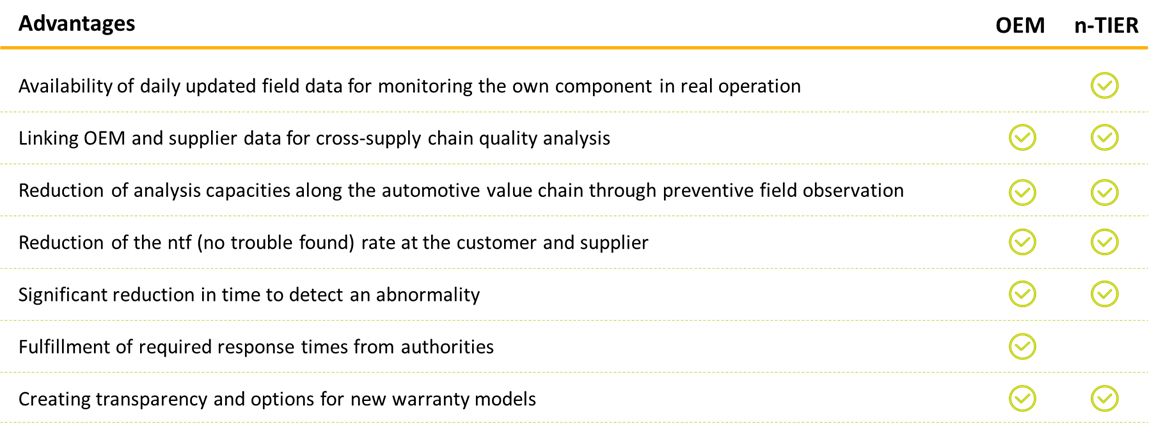

| Advantages | For OEM | For n-Tier |

|---|---|---|

| Availability of daily updated field data for monitoring the own component in real operation | X | |

| Linking OEM and supplier data for cross-supplychanin quality analysis | X | X |

| Reduction of analysis capacities along the automotive value chain by preventive field observation | X | X |

| Reduction of the NTF (no trouble found) at the customer and supplier | X | X |

| Significant reduction in time to detect an abnormality | X | X |

| Fulfillment of required response times from authorities | X | |

| Creation of transparency and options for new warranty models | X | X |

OEM and large automotive suppliers

The Quality KIT from Catena-X enables companies to realize trustful and sovereign data exchange with their partners and utilize the data in a cooperative way for an Early Warning of known and unknown quality issues. Root causes can be analysed und understood much faster what leads to an earlier and focussed counter measure. In sum companies can realize economic benefit by reduction of warranty costs while at the same time increasing customer satisfaction due to a maximum availability of vehicles, products and services.

SME

The defined standards like data models and data exchange pipelines enforce a flexible and low-barries approach to integrate quality use cases and features according to SME need. An easy access to analytic capabilities or transparent analytic results from partner companies leads to an economic benefit from warranty costs reduction via faster on more focused activities related to quality issues.

Solution Provider

Solution providers have the potential to scale customer groups via platform effects and standardization of data models and their exchange. Additional new market potentials can be accessed via marketplace and shared service network.

Example: Benefits of using early warning and root cause analyses in active field monitoring of a vehicle component

OEM A and supplier B agree to carry out quality analyses with field data from the OEM and production data from the supplier based on Catena-X Use Case Quality Methodology (live control loop see above) and with Catena-X-certified tools. For this purpose, a quality case with framework conditions is agreed to in the use case. A component and the associated data are selected. After technical and organizational onboarding and the agreed data exchange, the joint analysis room is available and collaborative quality work can be started.

In general, one of the partners carries out continuous monitoring of the components using the common database. This allows, for example, error messages in the vehicle, repairs and claims to be monitored and anomalies are immediately visible.

In our example, an engine component passes on various error messages (DTCs = Diagnosis Trouble Codes) to the vehicle via the central engine control unit. After 4 weeks, it is visible in the Catena-X certified tool that a DTC in the field is slowly but steadily increasing. With Catena-X Tooling, this is immediately recognized, although no increasing workshop visits and repairs are yet visible in the database. An employee of a partner immediately notices this and shares this observation with the joint team. At the same time, the employee begins to clarify through initial analyses whether the anomaly is actually a problem. Since it quickly becomes clear from the data that this is a potentially critical fault pattern with the result of increasing repair cases and that a replacement of parts may be necessary, the employee reports this to the joint team (early warning).

The team decides to carry out a root cause analysis together. Various hypotheses about the cause of the fault are examined: running times are compared, software levels, environmental conditions at the time the fault occurred, etc. The cause of the fault is a diagnostic algorithm modified in a software update, which results in the abnormal DTC appearing more often in the field at hot temperatures. This is caused by the production of vehicles from a certain point in time with the new software version or the installation of a new software version for vehicles in the field, e.g. during a service visit to a workshop.

As a jointly defined corrective measure between OEM and supplier, a modified algorithm will be integrated into the next regular software update. This starts as soon as possible in vehicle production and vehicles with the faulty software version receive a software update the next time they visit the workshop. For this purpose, repair shops are informed that the displayed error (DTC) for a particular software version is a software problem and does not require any repair. This minimizes costs due to unnecessary repairs.

The affected component continues to be monitored regularly. After a few months, there is a decrease in the conspicuous DTC corresponding to the reduction in the number of vehicles in the field with the faulty software version (proof of effectiveness of the corrective measure adopted).

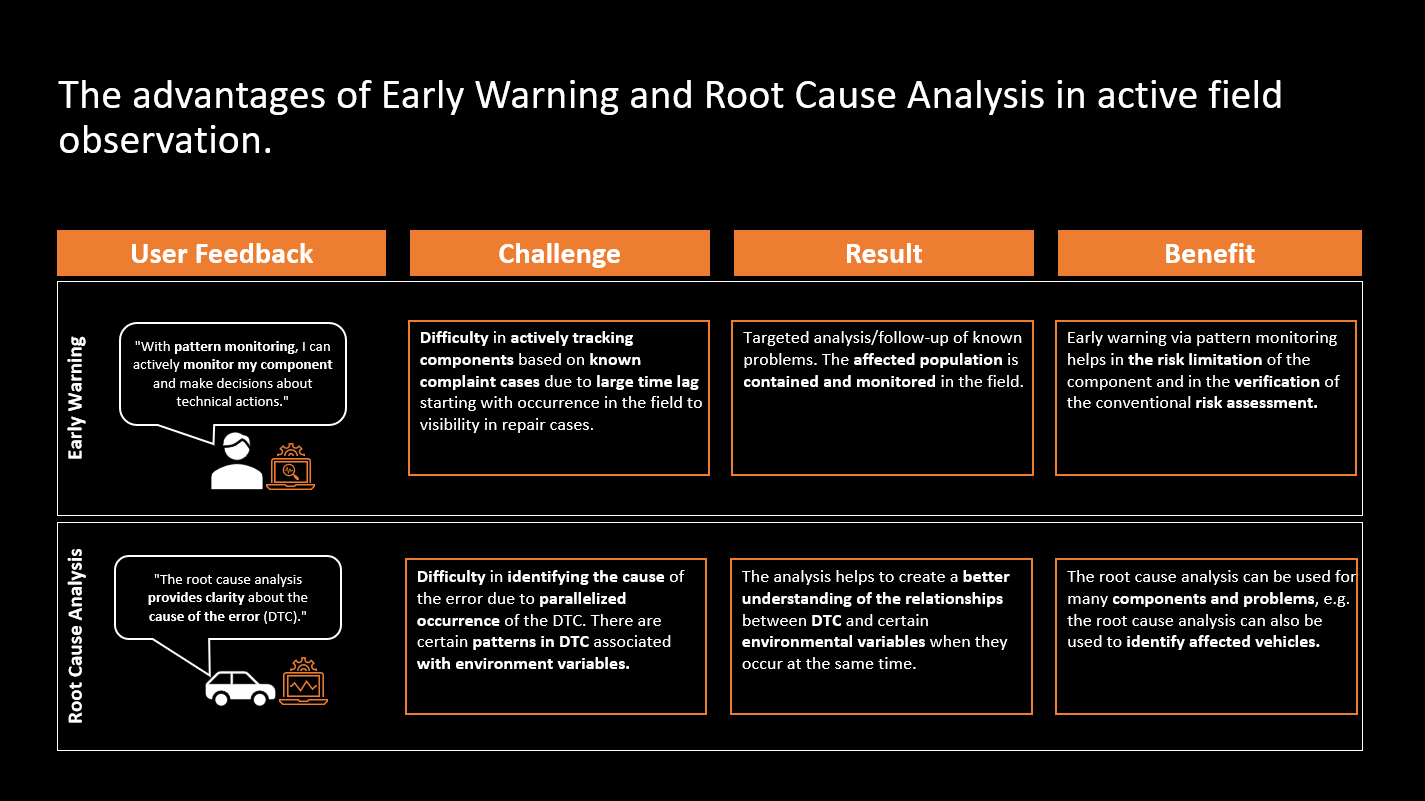

The image below shows user feedback, challenges, results and benefits of the new data-based way of working using the example of the Early Warning & Root Cause Analysis process steps.

Conclusion:

The example impressively shows that with the Catena-X methodology (live control loop), quality problems can be identified earlier, the causes of faults can be found more quickly, corrective measures can be carried out in a more targeted manner and the affected vehicles can be narrowed down more precisely. There are similar examples of the conversion of production parameters at the supplier or design errors in the design of vehicle components.

(Source: The example is based on real project results from piloting the Catena-X methodology at an OEM with 5 selected suppliers)

Tutorials

The following videos gives an overview of the presented Quality Improvement Use Case.

Overview about how Quality Management is improved by Catena-X

For more technical details take a look at the video in the Operation View

Data driven Quality Management with Catena-X - Statements from the consortial partners

Semantic Models

Semantic Structure

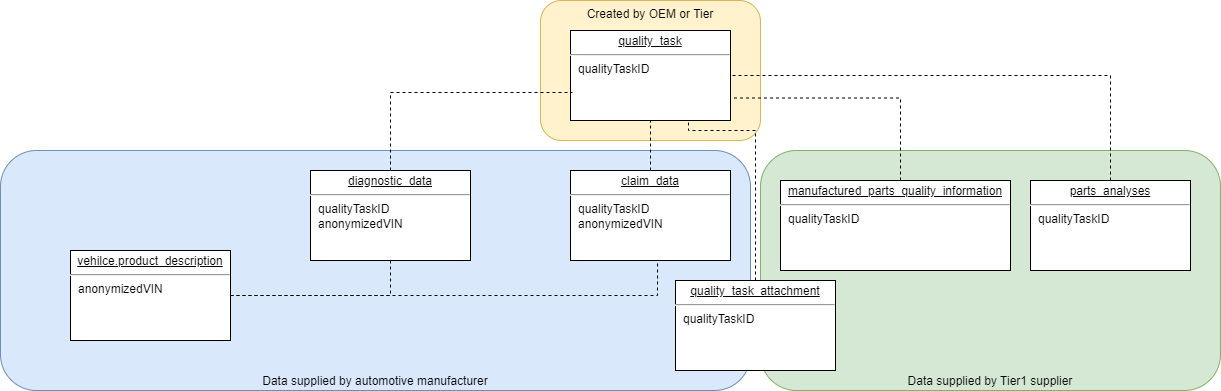

Overview Data Model Entities

Download for MS Excel: Quality_KIT_DataModelOverview_v1.0.xlsx

Common Data

Data structured in the following semantic models are to be delivered by OEM & supplier.

Quality Task

Quality Task is the root element and describes why companies are working together on a quality topic and what they want to do. All involved companies and their contact people are named. In addition, a flag tells what should be done with exchanged data after a Quality Task is closed. A Quality Task (qTask) can be created by both OEM or Supplier and defines why data is exchanged between two or more companies and what insights should be generated out of the transferred data. In addition, there is a flag what happens with the transferred data when this qTask is closed.

Github Link to semantic data model: CX-00036 Quality Task

Quality Task Attachment

Quality Task Attachment gives the ability to share data that is not standardized in an existing semantic model yet. Non standardized data provisioning is realized as a file transfer. The model contains file parameters and the schema of structured data in the provided file. A Quality Task Attachment can be provided by both OEM or Supplier.

Github Link to semantic data model: CX-00092 Quality Task Attachment

OEM Data

Data structured in the following semantic models are to be delivered by OEM.

Fleet Vehicles Product Description

Master data for each vehicle of a specific population - from an end customer view. This model represents the vehicle as it was sold to the customer. All entities and properties are constant over the lifetime of the vehicle.

Github Links to semantic data models:

CX-00037 Vehicle Product Description

Fleet Diagnostic Data

Data model for vehicle diagnostic data suitable for mass data transfer. Diagnostic data coming from multiple vehicles that are affected by an quality issue + Diagnostic data from similar vehicles that are not affected by an quality issue.

Github Link to semantic data model: CX-00038 Fleet Diagnostic Data

Fleet Claim Data

Customer complaints that are linked to this QualityTask +Data about the exchange of potentially faulty parts.

Github Link to semantic data model: CX-00039 Fleet Claim Data

Supplier Data

Data structured in the following semantic models are to be delivered by Supplier (Tier n).

Manufactured Parts Quality Information

A selection of manufacturing-related parameters that help to solve a quality issue.

Github Link to semantic data model: CX-00041 Manufactured Parts Quality Information

Parts Analyses

Analyses results of replaced and potentially faulty parts, that are linked to this Quality Task.

Github Link to semantic data model: CX-00040 Parts Analyses

Logic & Schema

Business Logic

The prerequisite for faster faster problem solving is the earliest possible detection of a problem (early warning) and the fastest possible understanding of the error chain and cause (root cause analysis). Early Warning in general has to be realized at all relevant points along the value chain.

Early Warning in the Field, an early warning system for issues in a vehcile fleet, enables the earliest possible detection of quality problems in products in vehicles after delivery. Vehicle data from the OEM is used for the analysis, in particular fault codes that are stored in ECUs and read out during a workshop visit or frequently "over the air". Increases in product-specific fault codes across the vehicle population provide a reliable indicator of quality problems much earlier than through parts replacement and analysis.

Early Warning in the Production focuses on early detection in the production of products. Various practical scenarios have been developed and the corresponding technical requirements specified. If, for example, a supplier discovers that a delivered product has a quality defect, the customer can be informed by means of notification. The functionality of traceability (Catena-X Use Case Traceability) in the supply chain makes it possible to trace in which vehicle or follow-up product the affected components are installed. Remedial measures can thus be applied specifically to a limited quantity.

If a problem is detected by early warning in the field or in production, a data-based Root Cause Analysis is started. The aim is to derive hypotheses regarding the cause and effect relationship from the shared database of the customer and supplier and to verify them together. With the Catena-X network functions, this transparency can be achieved much faster. If the root cause is known more quickly, effective counter measures can be defined and implemented much faster.

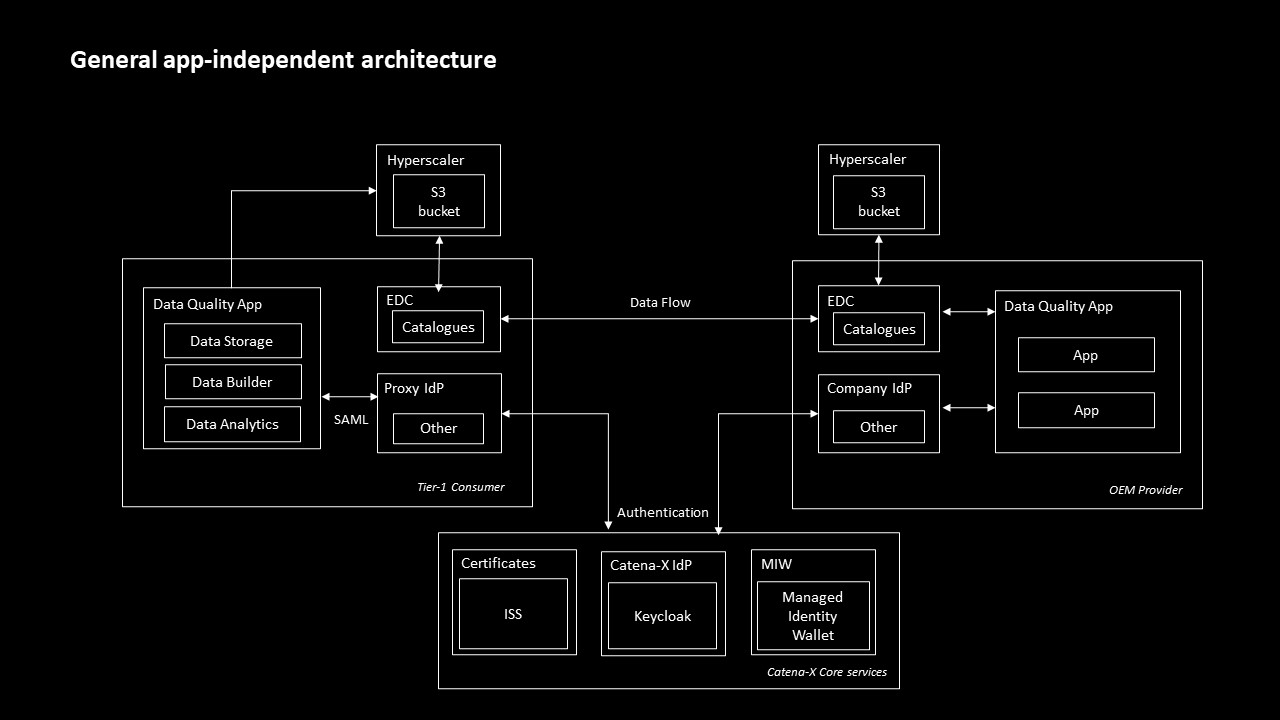

Architecture Overview

The tier-1 receives data on vehicle master data, existing claims and DTCs. Once the data is received, the Tier-1 supplier is analyzing the data in order to detect patterns based on which DTCs and claims can be explained. The data is shared and consumed as assets via the companies' EDC while the authorization is managed via the the shared services of the consortia.

Quality Components

| Subsystem | Description |

|---|---|

| Data Provisioning | This component provides a company's data to the Catena-X network by transforming it into the Catena-X format and publishing it. In Catena-X, data must be provided to the network based on existing standards from the other Kits. One example that can be used is the Connector KIT that builds a component based on the IDS protocol, e.g. the Connector of the Eclipse Dataspace Components (EDC). The data format used for Quality data is based on the aspects (Sub-)models published in the Semantic Hub. |

| Internal Systems | Existing internal systems of a Catena-X partner which provide data to Quality components. - For Data Provisioning: The data provided to Catena-X via the EDC should be fetched from a partner's internal system. e. g. quality claims, defect code collection system |

| Quality App | Enables traceability functionalities like quality alerts or notifications. When a Traceability App fetches data for digital twins (submodels), there are two options: - Directly access the partner's EDC (and the Digital Twin Registry) to connect to other partner's EDC and retrieve the data from ther - Use a local IRS service to get the data and let the IRS handle the EDC and Digital Twin Registry communication. |

Catena-X Core Services

| Subsystem | Description |

|---|---|

| Eclipse Dataspace Components (EDC) | The Connector of the Eclipse Dataspace Components provides a framework for sovereign, inter-organizational data exchange. It will implement the International Data Spaces standard (IDS) as well as relevant protocols associated with GAIA-X. The connector is designed in an extensible way in order to support alternative protocols and integrate in various ecosystems. Repository of the Catena-X specific EDC. |

| SSI → MIW | The Self-Sovereign Identity is also a life long identity,( when credentials are created and the MIW is not reachable) , the other verifiers should be able to check and validate exisiting valid credentials from distributed databases, directory or DLT. The MIW (also called "Custodian") provides a private/public key pair and related DID for a legal entity along with the onboarding. |

| Discovery Service | The EDC / dataspace discovery interface is a CX network public available endpoint which can get used to retrieve EDC endpoints and the related BPNs, as well as search for endpoints via the BPN. |

Business Process

To realize the Business Logic described in the Quality Kit

all steps of the Business Process (described in the Development View), like data provisioning and consuming by the involved partner companies, are realized in compliance with the Catena-X Data Governance Framework. Under this link you can find the latest version of the framework regulations as download. The documents are seperated in the following levels:

Data Space Level: 10 Golden Rules of Catena-X

**Use Case Level **: Quality Management specific policy as download.

Data Offering and Usage Level are defined by bi-lateral aligned policies and contracts between the cooperating partner companies. Content is currently in definition.

Standards

Our relevant standards can be downloaded from the official Catena-X Standard Library:

-

CX - 0041 Semantic Model Manufactured Parts Quality Information

-

CX - 0071 Triangle Quality Early Warning Field and Root Cause)

Notice

This work is licensed under the CC-BY-4.0.

- SPDX-License-Identifier: CC-BY-4.0

- SPDX-FileCopyrightText: 2023,2023 ZF Friedrichshafen AG

- SPDX-FileCopyrightText: 2023,2023 Robert Bosch GmbH

- SPDX-FileCopyrightText: 2023,2023 Bayerische Motoren Werke Aktiengesellschaft (BMW AG)

- SPDX-FileCopyrightText: 2023,2023 SAP SE

- SPDX-FileCopyrightText: 2023,2023 Siemens AG

- SPDX-FileCopyrightText: 2023,2023 Volkswagen AG